Unique, "EB on Breast"

Unique, "EB on Breast"1787 Brasher Doubloon from

The Gold Rush Collection

The Minting Process

Miners were apt to deposit gold in the natural state (i.e., dust and/or nuggets), while bankers and merchants were likely to have other forms as well, including gold bars and foreign gold coins. After a receipt was issued for the deposit, mint personnel melted the gold into a homogenous mass, from which an assay slip was used to determine the fineness. Then the value of the deposit, and the corresponding equivalent in coin, was determined. The deposit was then alloyed to standard (.900) fineness by adding copper, and if necessary, silver, both of which typically carried a charge. As gold from the local fields was above the standard fineness, parting (i.e., separating out the silver) was not usually required. It was typical at Dahlonega to leave in the naturally occurring silver, and make up the balance with copper. As standard mint practice, the silver content was kept between 25 and 50 parts per thousand.

The gold melt was then cast into ingots, annealed, and passed through a rolling mill, which reduced the thickness. The resulting strip was passed through a die in the drawing bench, which resulted in a strip of gold of the proper thickness, from which planchets were cut.

The gold melt was then cast into ingots, annealed, and passed through a rolling mill, which reduced the thickness. The resulting strip was passed through a die in the drawing bench, which resulted in a strip of gold of the proper thickness, from which planchets were cut.

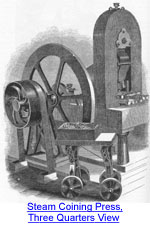

After the planchets were cleaned and annealed, a steam press, located in the first floor Press Room in the rear portion of the building, struck the coins at the rate of 50-60 per minute.

The presses were so heavy that large posts had to be propped under the floor joists in the basement to keep the floor from sagging. The power to turn the press was transmitted from a belt running through the floor from the basement Engine Room, and which was connected to a steam engine.

There was a well in the basement that supplied water to the boiler. Assay coins (one for every 500 produced, with at least one from every melt) were set aside to be sent to Philadelphia. The coins could then be paid to the depositors.

Many Dahlonega coins exhibit mint-caused defects such as weak strikes and various planchet irregularities. There are several potential causes for these imperfect coins. It has been suggested by some scholars that the Philadelphia Mint, which prepared the dies, including the addition of dates and mint marks, had a practice of shipping substandard dies to the branch mints, rather than destroy them or put them in use at Philadelphia. While this may have occured, a close look at the objective evidence suggests that defective dies were not the primary cause of the weakly struck coins. There are many examples of both strong and weak strikes having come from the same die. However, there is considerable evidence in the correspondence from the Dahlonega Mint concerning mill rollers which were too soft (and did not produce quality planchets) and defective supplies of copper. The latter is thought to have caused "work hardening" of the planchets, which means that the metal would not flow properly into all design areas of the die. The Dahlonega Mint did have a considerable problem with dies cracking excessively, however.